High Temperature Paint

High Temperature Paint

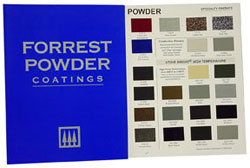

ACADEMIE DU FEU / SCR Refractories is the European distributor of paints Stove Bright high temperature, produced for over 30 years by Forrest Paint, the leader in the U.S. market with over 85% market share. Stove Bright offers over 20 standard colours, including four variations of black, allowing professionals to offer various finishes and customisation of the final product.

Stove Bright also has a range of products for the heating industry, including high temperature powder coatings, high temperature paints, water-based products and various maintenance and cleaning products.

High Temperature Paint 650°C

High Temperature Paint 650°C

Download 51H - 62H series product data sheet

Download Aerosol Material Safety Data Sheet

Download Bulk Material Safety Data Sheet

Stove Bright® High Temperature Paint is the industry’s premier high temperature paint. It is formulated with a unique blend of heat resistant pigments in a silicone polymer resin that provides excellent colour retention and film integrity in working temperatures up to 650°C. Stove Bright® High Temperature Paint is designed for rapid curing and great working properties over ferrous metal surfaces. It is ideal for wood, pellet, and gas stoves as well as stove pipes, engines, engine manifolds, and many other metal substrates that are subject to high temperatures. Available in a wide range of colours to suit almost any need, and comes in both easy to use aerosol and brush-on formulas to accommodate any project.

Stove Bright® High Temperature Paint is the industry’s premier high temperature paint. It is formulated with a unique blend of heat resistant pigments in a silicone polymer resin that provides excellent colour retention and film integrity in working temperatures up to 650°C. Stove Bright® High Temperature Paint is designed for rapid curing and great working properties over ferrous metal surfaces. It is ideal for wood, pellet, and gas stoves as well as stove pipes, engines, engine manifolds, and many other metal substrates that are subject to high temperatures. Available in a wide range of colours to suit almost any need, and comes in both easy to use aerosol and brush-on formulas to accommodate any project.

- Silicone formula retains colour with extended exposure to 1200°F

- High quality, fast drying formula resists scratching

- Used by the leading stove manufacturers as their factory finish

- Available in 400 ml aerosols, 1 or 5 gallons pails (3.785 or 18.925 litres)

| Surface | Appropriate | Recommended pre-treatment |

| Steel | Yes | Sandblast / Degrease / Clean with solvents |

| Cast iron steel | Yes | Sandblast / Degrease / Clean with solvents |

| Galvanized steel | No | |

| Galvan (Zn 95%, Al 5%) | Limited* | Degrease / Clean with solvent |

| Galvaum | Limited* | Degrease / Clean with solvent |

| Aluminium | Limited* | Sandblast / Degrease / Clean with solvents |

| Cast iron aluminium | Limited* | Sandblast / Degrease / Clean with solvents |

| Stainless steel | Depends on surface | Sandblast / Degrease / Clean with solvents |

| Ceramics | Depends on porosity | Aucun |

| Fire stone | Yes, test first | Aucun |

* carry out tests

Colours and references

1990 1A62H290 SATIN BLACK

1990 1A62H290 SATIN BLACK

6159 1A62H059 METALLIC BROWN

6193 1A60H993 METALLIC GRAY

6196 1A52H450 METALLIC BLUE

6197 1A52H060 MOSS GREEN

6198 1A52H700 FOREST GREEN

6199 1A60H300 REDWOOD

6201 1A62H201 CHARCOAL

6223 1A52H063 EMERALD GREEN

6230 1A62H830 GOLDENFIRE BROWN

6265 1A51H030 SILVER

6283 1A53H500 ALMOND

6298 1A62H898 RICH BROWN

6302 1A52H068 GOLD

6304 1A51H200 FLAT BLACK

6306 1A54H050 PRIMAIRE H.H. PRIMER

6307 1A53H800 SAND

6309 1A62H209 METALLIC BLACK

6311 1A62H085 HONEY GLO BROWN

6313 1A52H083 MAUVE

6319 1A60H350 MOJAVE RED

6320 1A52H050 COPPER

6321 1A53H031 PEWTER

6324 1A62H051 SUNSET

6325 1A62H081 SURF SAND

6327 1A53H071 GREEN ILLUSION

6329 1A52H082 SHIMMERING ROSE

Heat Resistant and High Temp powder

Heat Resistant and High Temp powder

Forrest Paint unique experience in high-temperature applications has enabled them to develop leading high temperature powder technology. They offer a full line of heat-resistant powder coatings in many colours, textures and gloss levels. Medium temp products are available to meet requirements up to 300°C. High temperature silicone powder coatings provide service up to 650°C. They offer an attractive and extremely durable finish in a safe, efficient and environmentally friendly coating technology. Stove Bright high temperature powder coatings are used by manufacturers of stoves, stove pipes, heaters, engine and exhaust systems.

1PC-607 series Polyester based

Brightness : high gloss (80%) - Service temperature : 230°C

This product is formulated in a full range of gloss and textured effects. It is suitable for steel and aluminium substrates. This medium heat resistant coating is designed to provide continuous service between 180°C and 200°C and intermittent service up to 230°C.

- Excellent flow, flexibility and electrostatic application properties

- Good colour and gloss retention at service temperature

- Good UV resistance for outdoor us

Almond 1PC-607-1590

Black 1PC-607-2930

Black Texture 1PC-607-2940

1PC-619 series

Epoxy based

Brightness : low (3 à 4%)

- Service temperature : 280°C

This decorative coating is designed for fireplaces and general interior use. This medium service temperature formulation contains a blend of resins and pigments designed to provide continuous service up to 200°C and intermittent service up to 280°C.

- Excellent surface hardness at service temperature

- Excellent colour and gloss retention

- Excellent flow and product stability

Flat Black 1PC-619-2220

Metallic Black 1PC-619-2090

Anthracite Black 1PC-619-2190

Anthracite Black Texture 1PC-619-2191

1PC-653 series

Silicone based

Brightness : low to medium (5 to 30%)

- Service temperature from 420°C to 540°C

Series 653, unlike the other two series, is based on silicon and thereby supports temperatures up to 650°C. Its application is quite large, it can be used on stoves and fireplaces and is available in many colours and textures.

| Flat Black Texture | 1PC-653-2861 |

| Flat Black | 1PC-653-2860 |

| Almond | 1PC-653-8029 |

| Satin Black | 1PC-653-2890 |

| Silver Mini Texture | 1PC-653-0225 |

| White | 1PC-653-1023 |

| Creme | 1PC-653-1047 |

| Granite | 1PC-653-2028 |

| Semi Gloss Black Texture | 1PC-653-2861 |

| Metallic Black | 1PC-653-2863 |

| Flat Black Texture | 1PC-653-2865 |

| Flat Black Texture | 1PC-653-2866 |

| Flat Black | 1PC-653-2880 |

| Black Gloss 10% | 1PC-653-2890 |

| Black Gloss 30% | 1PC-653-2900 |

| Burgandy | 1PC-653-3038 |

| Multi-spec dark brick | 1PC-653-3411 |

| Multi-spec rust | 1PC-653-3041 |

| Terracotta | 1PC-653-3039 |

| Dark brick | 1PC-653-3042 |

| Blue | 1PC-653-4027 |

| Brownstone #2 | 1PC-653-5015 |

| Forrest Green | 1PC-653-7007 |

| Green Texture | 1PC-653-7057 |

| Linden green | 1PC-653-7061 |

| Light stone | 1PC-653-8059 |

| Light brownstone | 1PC-653-8076 |

| Brushed bronze | 1PC-653-8083 |

| Brownstone | 1PC-653-8088 |

| Beige | 1PC-653-8096 |

| Gray | 1PC-653-9057 |

| Graystone | 1PC-653-9081 |

| Rusty multi-spec | 1PC-653-8116 |

| Rusty brown | 1PC-653-8117 |

Similar to the high temperature liquid, the high temperature powder coatings are heat rated based on their colour. All of these powder coatings will have good adhesion and physical properties up to 650°C degrees, however the lighter colours will darken around 300°C degrees. For example, Almond would not be a good choice on a wood stove which operates at 600°C degrees, because it will start to discolour.

Packaging : 50 US pound packs (eq. 22,67 kg).

We also have some 5 US pound packs (2,27 kg) to be use as samples.

Download powder coating 1PC-607 series product data sheet

Download powder coating 1PC-619 series product data sheet

Download powder coating 1PC-653 series product data sheet

Download Material Safety Data Sheet

Forrest Paint High Temperature Paints

Forrest Paint High Temperature Paints

Forrest Paint

Forrest Paint Co. was established in 1973 in Eugene, Oregon. Their customers include distributors, contractors, and equipment manufacturers regionally, nationally, and internationally.

They offer a variety of liquid and powder coatings, with the ability to provide products formulated to meet the users’ needs in a timely manner. Consistency and innovation drive Forrest Paint Co. to provide excellent core products, as well as promote new specialized goods.

Forrest Paint is a pro-active, ecologically responsible, manufacturing company. Additionally, they are a leader in high performance coatings for use on wood, metal, plastics, and other substrates. These products are packaged in aerosols or bulk quantities. Forrest Paint has established a global reputation with the Stove Bright® hearth product line. They currently serve customers on five continents through twelve warehouses worldwide. Académie du Feu / SCR Refractories are their European distributor.

Their unique experience in high temperature systems enables Forrest Paint to be on the cutting edge of heat-resistant coating technology.

Forrest Paint is backed by tremendous technical support. The laboratory consists of departments in metal, wood, and powder, providing quality control and dynamic research and development. Liquid products include UV Cured, Water Reducible, Low VOC, Low HAPS, Epoxies, Urethanes, High Temperature coatings, Primers, Alkyd Enamel Systems, and many other products engineered for specific applications.

Their powder coatings line includes Polyesters, Epoxies, Hybrids, and Polyurethane’s. Stove Bright® high temperature powder can withstand environments exceeding 650°C.

Finally, they pride themselves on compliance with all known regulations concerning safety, labelling, and environmental laws. Forrest Paint Co. is a leader in these areas, and will continue to be at the forefront of product and environmental progress.